Vad gör att en fläck är tvättbeständig för barns kläder? Nyckelfaktorer: Limtyp, stygnstäthet och baksidematerial Vad gör att barns fläckar klarar tvättomgångar? Tre huvudsakliga faktorer spelar in: vilken typ av lim som används, hur tätt stygnen är...

VISA MER

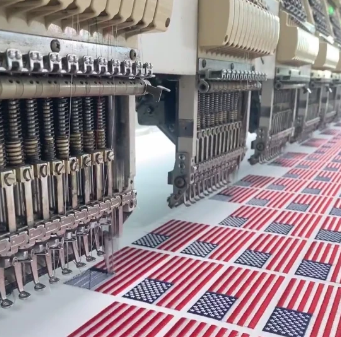

Varför är prototyper av broderade fläckar på 5 dagar nu möjliga? Övergången från traditionella produktionsbottlenecks till digitala arbetsflöden Förut innebar tillverkning av broderade fläckar veckolånga väntetider eftersom allt gjordes manuellt steg för steg...

VISA MER

Vad betyder MOQ för anpassade strykbara fläckar? Minimum Order Quantity (MOQ) är den minsta partistorlek en tillverkare kommer att acceptera för anpassade strykbara fläckar. Leverantörer sätter MOQ:n för att täcka fasta produktionskostnader – inklusive konvertering av konstverk till digital form, maskininställning...

VISA MER

Vad är 3D-reliefförslag med kardborr – och varför de sticker ut Kardborrstecken med 3D-relief kombinerar struktur med den pålitliga klibbiga egenskapen hos krok- och loopsystem, vilket gör att de sticker ut både visuellt och vid beröring. Detta är inte dina vanliga...

VISA MER

Vetenskapen bakom varför smältpålägg inte sitter kvarVarför de flesta smältpålägg lossnar efter 20–30 tvättar: nedbrytning av limet kontra mekanisk påfrestningDe flesta smältpålägg börjar lossna efter ungefär 20 till 30 tvättar eftersom det faktiskt finns två problem...

VISA MER

Värmeaktiverat limsystem i strykbara plåster Strikplåster fästs vid tyger genom termoplastiska polymerskikt som aktiveras vid specifika temperaturer (vanligtvis 300–350°F). När de värms upp blir limmet flytande och tränger in i tyget...

VISA MER

Förståelse av broderade hattplåster och deras potential för anpassad design Vad är broderade plåster och varför dominerar de anpassad hattdesign? Broderade hattplåster består i grunden av tygdesigner som skapas genom att sy färgade trådar på ett tätt bakgrundsty...

VISA MER

Förståelse av standardproduktionstid för hattar med anpassade plåster Vad är den genomsnittliga leveranstiden för hattar med anpassade plåster? Hattar med anpassade plåster skickas vanligtvis ut efter ungefär 10 till 15 arbetsdagar från det att vi får klartecken för den slutgiltiga designen...

VISA MER

Vad gör att Velcro-fästen kan återanvändas? Krok-och-slagsnäcksfästen uppnår återanvändbarhet genom sin tvådelade design. De små plastkrokarna på krokssidan fäster sig i polyester- eller nylonloopar, vilket skapar starka men omvändbara förband. Högkvalitativa patchar...

VISA MER

Vad är 3D-relieff anpassade broderade patchar? Förståelse av 3D-broderade patchar Tredimensionella broderade patchar tar vanliga platta design och förvandlar dem till något som kunder faktiskt kan känna när de bär märkeskläder. Vad som gör det...

VISA MER

Att välja färgbeständiga trådar för broderade skräddarsydda kepsar Varför broderitrådar blekner med tiden Broderitrådar tenderar att brytas ner över tid på grund av flera faktorer, inklusive solljus, kemikalier och fysisk nötning. Solljuset är faktiskt en av de största...

VISA MER

Materialval: Att bygga grunden för hållbara broderade märken. Polyester twill och nylon: Högstyrka tyger för robusta sportklädesapplikationer. För industriella broderade märken är polyester twill och nylon främsta val eftersom t...

VISA MER